Transforming Food & Beverage Operations

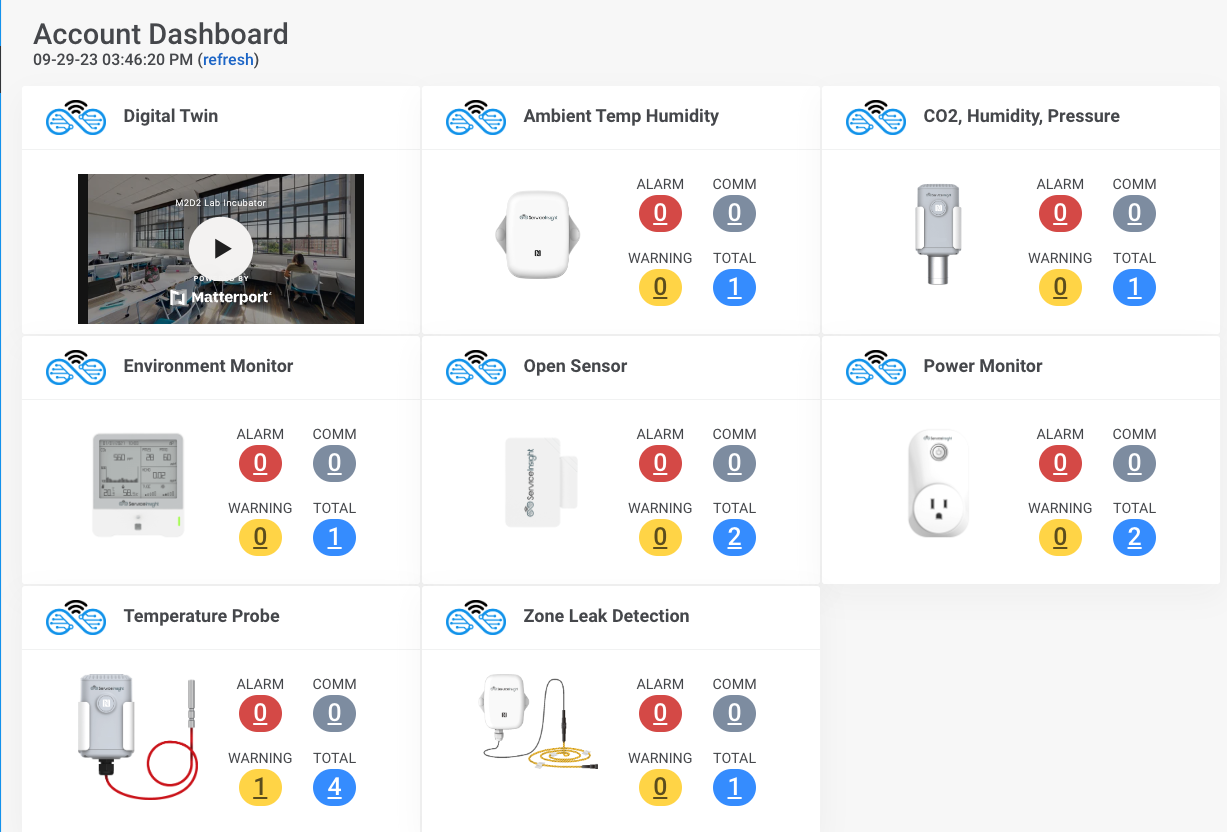

All your Production Operations metrics in one place

Monitor your production environments, storage temperatures and asset utilization from a single dashboard while increasing the efficiency, safety and sustainability of your operations.

- Alerting & Monitoring

- Digital Twin of Workspaces

- Raw Material Management

- Asset Tagging & Tracking

- Regulatory compliant reporting

Vineyards

Our devices offer indispensable benefits to vineyards grappling with environmental challenges. Real-time data from our sensors measuring temperature, humidity, and soil conditions enables winemakers to optimize irrigation amid water shortages. In fermentation tanks, our sensors detect leaks, monitor fermentation, and track temperature trends, aiding nuanced vineyard management.

Our devices streamline labor-intensive processes, such as visually identifying grapevine health issues. By efficiently predicting harvest times and aiding flavor development, Service Insight contributes to enhanced wine quality. Moreover, Service Insight's role extends to sustainability, as technological advancements in pest management reduce reliance on chemical pesticides, promoting biodiversity. In deploying Service Insight, vineyards prioritize both environmental and oenological excellence.

Breweries

Service Insight's IoT platform is a game-changer for breweries, offering real-time insights into critical parameters like temperature, pressure, and fermentation processes. This precision in monitoring allows brewers to maintain optimal brewing conditions, ensuring a consistent and high-quality end product. The platform's sensors detect anomalies, such as sudden temperature fluctuations or irregular pressure, enabling proactive intervention to address issues before they impact the brewing process. This not only safeguards product integrity but also minimizes downtime, contributing to increased operational efficiency.

Beyond production insights, Service Insight's platform extends its benefits to inventory management. By monitoring raw materials and finished products in real time, breweries can optimize supply chain operations, reducing waste and ensuring efficient resource utilization.

Production Efficiency

In the dynamic world of food and beverage, production efficiency is key. Service Insight's AIoT solutions are tailored to enhance your production processes. Our technology integrates seamlessly with your production equipment, providing real-time insights into their performance, maintenance needs, and resource usage. By harnessing this data, you can optimize production lines, reduce downtime, and ensure consistent product quality. Improved production efficiency leads to increased output, reduced costs, and a competitive edge in the food and beverage industry.

Quality Assurance

Quality assurance is non-negotiable in food and beverage production. Service Insight's technology ensures your products meet the highest standards. Monitor critical parameters such as temperature, humidity, and equipment condition to maintain the integrity of your products. Our solutions provide early alerts to potential issues, allowing for timely corrective actions and preventing costly recalls. By adopting our AI-driven insights, you can deliver safe, high-quality products that build trust among consumers.

Our Solutions for Food & Beverage

Elevate Your Operations with Service Insight

Service Insight is your partner in revolutionizing food and beverage production. By embracing our AIoT solutions, you're not only improving production efficiency and quality assurance but also practicing sustainable, eco-friendly operations. Join us in transforming the way you produce food and beverages, making your operations smarter, more efficient, and environmentally responsible.